Hypercar explained

The Hypercar category, a joint project of the FIA and the ACO, that back in 2018 was envisaged as the new top class of the FIA World Endurance Championship, had its debut in 2021, but it wasn’t until this year when this ruleset really came of age, attracting a raft of manufacturers

The 11th season of the FIA WEC features an impressive 13 full-season Hypercar entries from seven manufacturers, highlighting the ongoing growth of the world’s premier endurance racing series and proving that the Hypercar technical platform appeals to the manufacturers.

SHIFT IN REGULATORY APPROACH

So, what makes the Hypercar class so successful? The ruleset, accommodating cars built to LMH and LMDh technical regulations, represents a major shift in philosophy compared with the LMP1 class it replaced. It allows for far greater variety both in terms of technical approaches as well as the aesthetics of the cars, at the same time ensuring sporting equality and preventing cost escalation through the concept of performance windows.

Technical Regulations are focused on controlling performance outcome instead of setting design or geometrical restrictions, allowing manufacturers to choose cost-effective solutions as significant expenditures do not translate to performance gains.

This autonomy allows the automakers to maintain the spirit of the brand and remain relevant to their road car philosophy, but also to express potential in terms of creativity and innovation. Less rigid aerodynamic constraints established for the cars give them the option to incorporate styling elements into the design.

Similarly to the LMP1 class, both hybrid or non-hybrid power units with transmission to either rear or both axles are allowed.

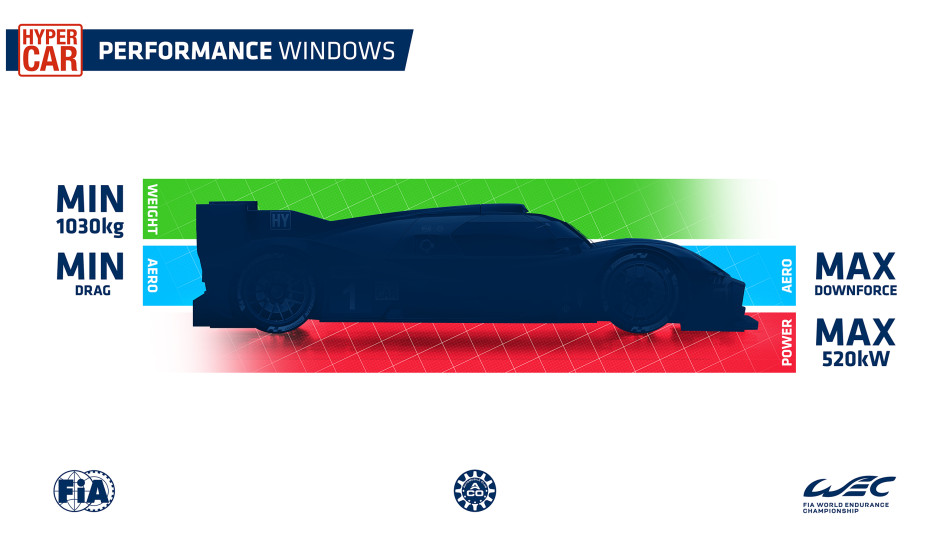

PERFORMANCE WINDOWS

The principle of performance windows is a new regulatory approach to the top category of the FIA WEC. It has been made possible by the application of precise modern methodology for measuring performance parameters, combined with the experience of efficient data acquisition and analysis processes.

Instead of constraining the design process with geometric requirements, the FIA and the ACO are overseeing the outcome. This is possible owing to the concept of performance windows, where minimum and maximum values were set for areas such as weight, power and aerodynamic performance, with each of the cars having to fit into those windows. The maximum power is set at 520kW, while the minimum weight at 1030kg.

During the homologation process, the cars are measured in the wind tunnel, the bodywork is scanned, while the engine performance is measured live on track with the use of torque sensors. This is to ensure that the cars fit into the performance windows.

The design of the cars is then “frozen” for their homologation cycle, ensuring they will remain unchanged through their life span.

As the performance targets are clearly defined, manufacturers can choose the most cost-effective technical solution without the additional burden of ultimate optimization around regulatory constraints.

TAILOR-MADE BALANCE OF PERFORMANCE

In order to ensure sporting equality, the FIA and the ACO rely on the Balance of Performance formula managed jointly by the two parties. The Hypercar BoP has been tailored specifically for the needs of the new category, leaning on the knowledge and experience gained over the years.

Both the FIA and the ACO have a long history of using BoP. The FIA started balancing out cars in GT racing in the mid-2000s and is constantly improving the process. Each year there are over 40 FIA-sanctioned events with BoP in use, varying from Cross-Country to GT racing. The best practices and learnings were taken into account in developing the Hypercar BoP.

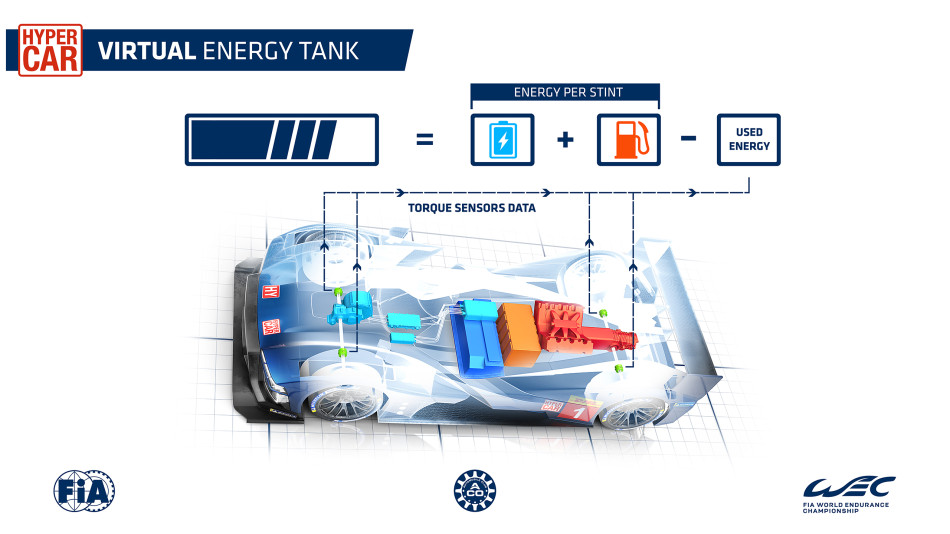

One of the most innovative solutions is the use of torque sensors, allowing for better control of powertrain parameters on track. These sensors, resistant to electromagnetic field and heat, are installed onto the driveshafts of the cars allowing calculation and monitoring of BoP-allocated energy per stint in real-time. This technology is effective in limiting development costs.

For 2023 a new methodology was adopted, with simulations and data from telemetry rather than the lap times playing the biggest role in the process of computing the BoP. To strengthen this approach, AVL was appointed as a technical partner, offering enhanced simulation abilities. The principle is to apply the exact same approach to balance every Hypercar against the others by capturing all measurable characteristics.

There will be only one BoP adjustment throughout the season using the same approach, after the 24 Hours of Le Mans, as well as possibly balancing out the LMH and LMDh platforms prior to that race.

COST-SAVING MEASURES

As avoiding cost escalation is one of the key targets behind the Hypercar concept, several other cost-saving measures were undertaken.

To start with, testing is supervised. The use of expensive materials and technology is greatly limited. The minimum weight for the gearbox is set at 75kg, with the use of magnesium or aluminium casing and bellhousing mandatory. Furthermore, lower power output results in lower power unit development costs

The suspension is also simplified, with a double-wishbone design compulsory and aids such as active systems and mass dampers forbidden.

There is also a single aero kit permitted, without the distinction for Le Mans and the other races. In order to avoid development costs, the tyres are exclusively supplied by Michelin.

SAFETY IMPROVEMENTS

With safety being the overriding priority for any FIA project, the Hypercar regulations feature a number of safety improvements.

Due to the high level of performance achieved by cars, all competitors must prove during homologation that their aerodynamics remain stable at different car attitudes, within the limits set by a table of critical speeds.

The LMP1 cockpit safety standards have been updated. The seating position is more upright, mitigating the risk of spinal injuries during serious accidents. This is the result of extensive research following several real-world accidents as well as accident simulation using the THUMS virtual human body model. In addition to seat load tests, seat belt anchorage load tests have been introduced.

Leg padding is now mandated and a new load test for the inboard leg protection panel has been introduced. In order to ensure increased energy-absorption capability during frontally-angled impacts, headrest coverage has been increased. The specification of the fuel tank bladder has also been upgraded.

Facebook

Facebook Twitter

Twitter